Production Capacity

Production base in Taiwan region exceeds 6,600 square meters

SMT foundry

3

Production line

Dressing and patching speed: total production capacity per day (24Hr)

6,468,000 PCS points

6,468,000 PCS points

DIP foundry

2

Production line

The maximum size of PCB that can be produced is L550mm*W410mm

Group test packaging line

30

Production line

The total manpower input per day (8Hr) is about 2,112,000Min

Factory equipment.

SMT

| Plate-Making Machine Solder paste printing machine SMD Piece-placement machine Solder Paste Inspection Flexible placer SM481-PLUS Midway Checkpoint Nitrous Gas Reflow Oven Unloader OFF-LINE AOI 160KV X-Ray Nitrogen generator |

3 |

DIP

| Lead-free plug-in line6M Lead-free repair line6M DIP JT-620 |

1 1 1 |

Assembly

| High frequency press machine Ultrasonic welding Printing machine Laser carving machine Steel printing |

15 6 1 6 2 |

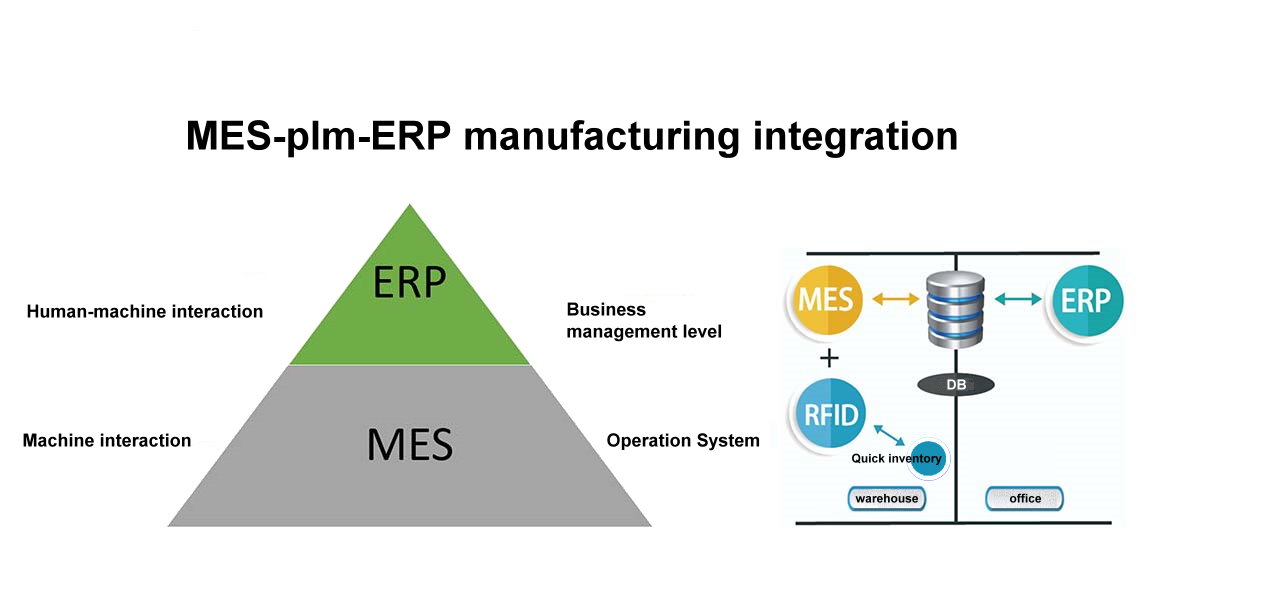

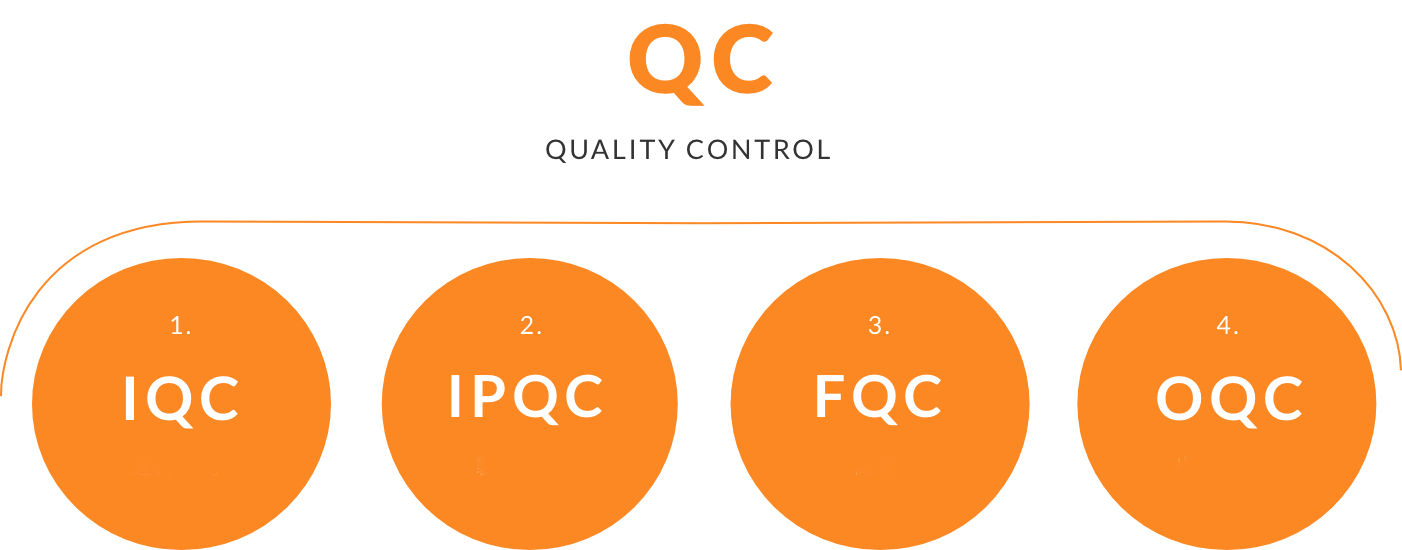

Quality Management System

The factory has a complete quality control and inspection process, from incoming materials, manufacturing, final inspection to shipment, to ensure that each product is within the specified and guaranteed standards from the development stage to mass production and shipment.

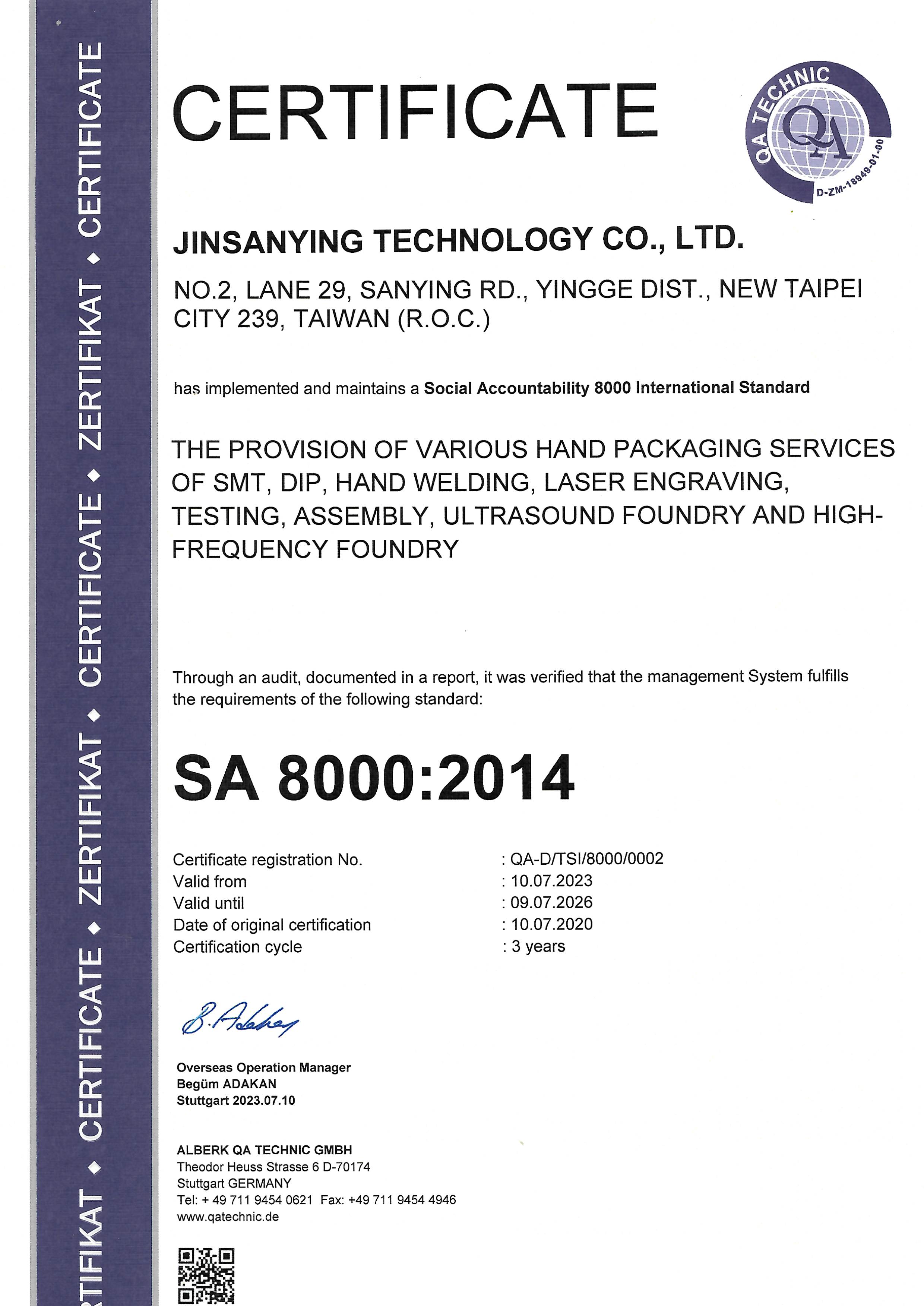

International Certification

ISO90001(EN)

ISO90001(TW)

ISO14001(EN)

ISO14001(TW)

SCI SA8000

ISO 13485